THE GRIND OF PROGRESS

At Beanspire, the journey toward improving coffee production has been marked by continuous growth, innovation, and a commitment to quality. In the 2017-2018 season, the company made a key investment in a wet mill operated by the Merlaeku family, a group of five brothers from the Akha Hilltribe minority. This investment gave Beanspire greater control over the process, beginning at the cherry stage, and allowed the company to source cherries from outside the family. The following year, in 2018-2019, the mill was upgraded with a roof, new pulpers, and improved workflows, streamlining the milling process. By the 2019-2020 harvest, Beanspire had taken further steps to enhance quality by investing in an electricity generator, building a cupping lab for farmers, and installing new concrete flooring.

In 2020-2021, the company leased additional space in the lowlands to improve drying efficiency. This decision proved to be crucial during the 2021-2022 harvest, when production increased by 20%, and the expanded drying space helped mitigate the effects of heavy rains that affected crop yields across Thailand. However, the 2022-2023 season presented a significant challenge. The climate crisis led to the lowest yields in years, driving prices to their highest levels. In 2024, the unpredictable effects of climate change and an influx of smuggled coffee from Myanmar and Laos flooded the market, leaving many farmers with surplus, unsellable coffee.

Despite these obstacles, Beanspire remains committed to supporting farmers, continuously refining processes, and adapting to an ever-evolving coffee industry.

CULTIVARS

Typica

ALTITUDE

1100 -1450 MASL

NOTABLE

The meticulous processing approach resulted in a much lower cherry-to-green-bean conversion ratio than usual. While the typical ratio is 15% (1:0.15), this lot had a conversion ratio of just 5% (1:0.05) due to the rigorous selection process.

PROCESSING

Natural : This natural processed microlot was crafted with precision. Cherries were floated to remove defects and laid in a one-inch layer on bamboo raised beds. Under-ripe and fermented cherries were continuously sorted out throughout the drying process. The cherries were raked multiple times daily and, after drying, were bagged to cure for two months before milling at our dry mill.

Kenya Style washed : This is done by extending the dry fermentation stage while minimizing the wet fermentation and soaking stages. Drying was done on bamboo raised beds for at least 14 days, then finished in the lowlands. For green coffee preparation, the beans went through a destoner, huller, size grader, and density table, followed by hand-sorting. The coffee was packed in triple-layered bags, consisting of a cotton outer layer, High-Density Polyethylene (HDPE) middle layer, and a hermetic inner bag to ensure freshness and quality during export.

Yellow Honey : This Yellow Honey microlot underwent a process designed to balance cleanliness with added body and sweetness. After harvesting, the cherries were floated to remove defects and pulped with water to remove about 50% of the mucilage. The parchment was dried on raised beds in thin layers, raked frequently to prevent fermentation and ensure even drying. Once the parchment reached a 10% moisture level, it was sent to our dry mill in the lowlands.

Cupping notes

2024 HARVEST

Beanspire - Doi Pangkhon Kenya-styled washed - Merlaeku.

-

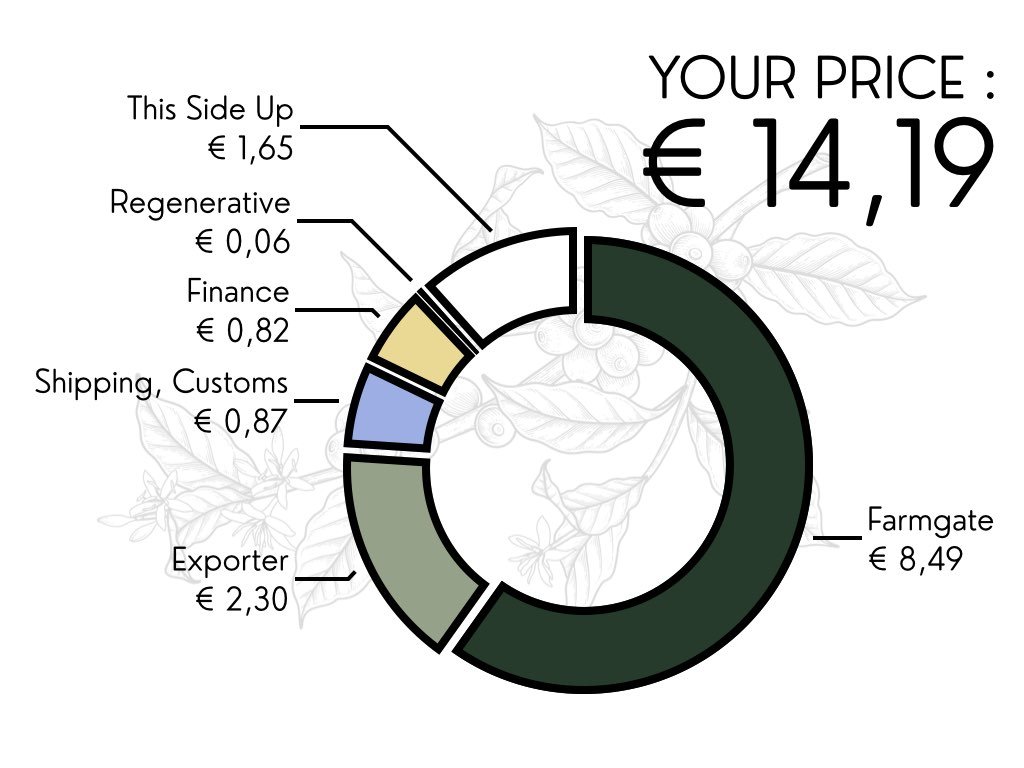

The price you pay for Doi Panghkon (p/kg). We agreed on this price directly with the farmers, disregarding the volatile US Coffee C price.

-

The farm gate price includes the payment to farmers for the coffee, wet milling, and margin.

Doi Pangkhon Kenya-styled Washed - Merlaeku :€ 7,79

Doi Pangkhon Yellow Honey : € 8,95

-

Beanspire collaborates with producers to mill their coffee, coordinate local freight from farm to port, and manage export paperwork, marketing and sales. The price break down also includes the cost of these services along with Beanspire's profit margin.

Doi Pangkhon Kenya-styled Washed - Merlaeku : € 1,38

Doi Pangkhon Yellow Honey :€ 1,84 -

Shipping is arranged from Lat Krabang Inland Container Depot in Thailand to Rotterdam, Netherlands, with all logistics and paperwork managed by Beanspire.

-

Average financing cost owed to (mostly social) lenders. This ensures immediate payment to the farmers when the coffee leaves the farm or port.

-

A standard TSU premium on all coffees designated exclusively to accelerate farmers’ own regenerative agriculture projects. Read more about the regenerative projects done by Rushashi here. (Webpage Coming soon)

-

This Side Up compensation for spending time and resources importing this coffee. Our work includes year-round contact with producers, managing export, shipping, import, warehousing, grading, sampling, finding and keeping roasting partners for Merlaeku. € 1,65 is This Side Up’s Model 1 markup. For a full overview of our modular margin construction, see the Trade Models page.

PHOTO GALLERY

You may use them freely to promote Merlaeku among your customers.